CNC (Computer Numerical Control) machining has revolutionized modern manufacturing, enabling precision, automation, and efficiency. Whether you’re a hobbyist or a professional, integrating the right hardware and software is crucial for optimal performance. One such powerful combination is the PoKeys57CNC motion controller paired with Mach3, a popular CNC control software.

This guide explores four essential topics to help you maximize your CNC setup:

What is PoKeys57CNC, and how does it enhance CNC control?

How do you understand and utilize the PoKeys57CNC pinout?

How do you configure Mach3 limit switches for safety and precision?

Where can you find a reliable Mach3 tutorial for CNC beginners?

Each section provides in-depth explanations, practical insights, and actionable steps to ensure smooth CNC operations. Whether you’re setting up a new machine or troubleshooting an existing one, this guide will serve as a valuable resource.

Let’s dive into the details, starting with an overview of the PoKeys57CNC and its role in CNC systems.

What is PoKeys57CNC, and How Does It Enhance CNC Control?

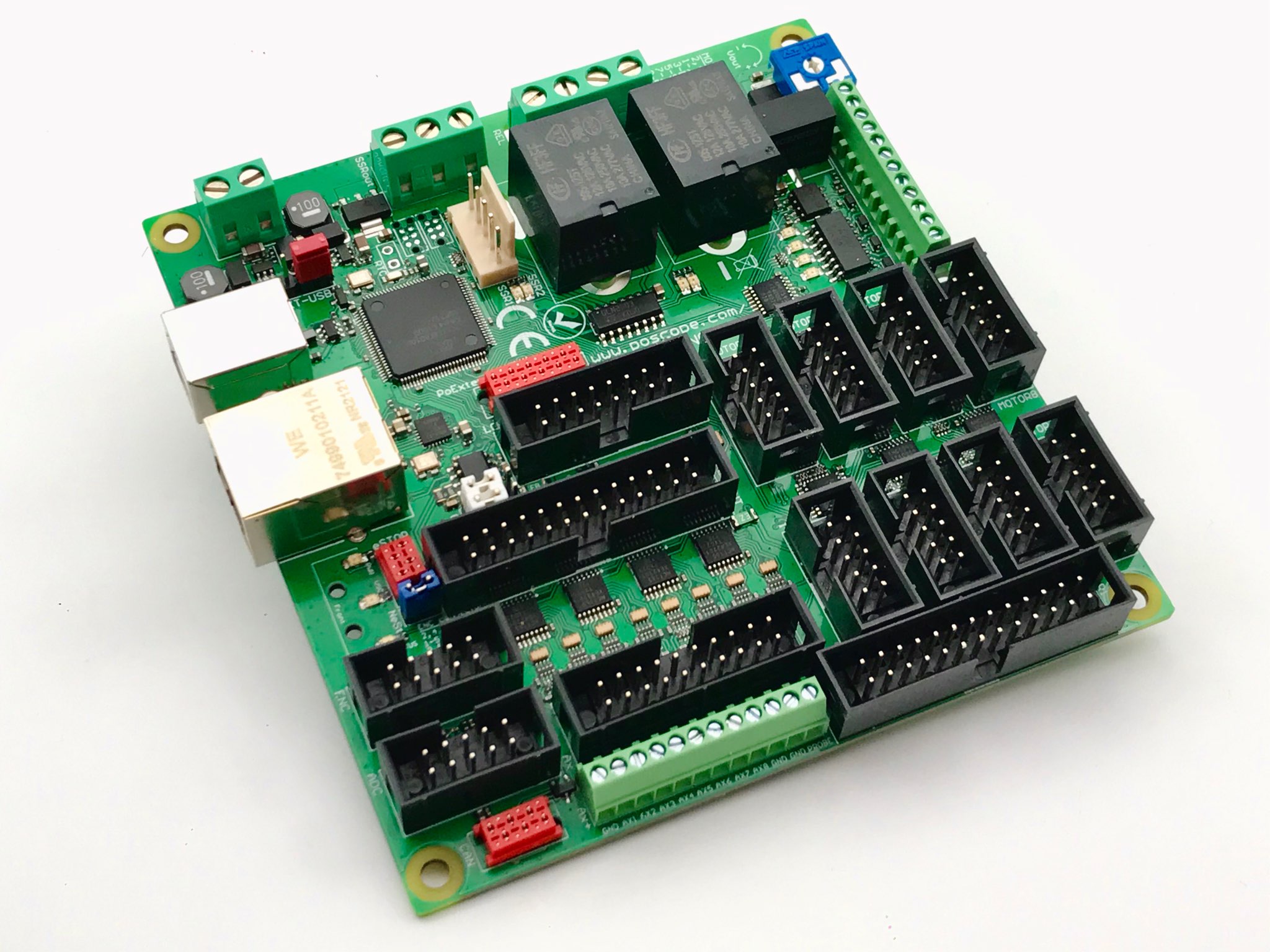

The PoKeys57CNC is a versatile motion controller designed to simplify and enhance CNC machine operations. It acts as an interface between your computer (running CNC software like Mach3) and your machine’s motors, sensors, and other peripherals. But what makes it stand out, and how does it improve CNC performance?

Key Features of PoKeys57CNC

Advanced Motion Control

The PoKeys57CNC supports up to 6 axes of motion, making it suitable for multi-axis CNC machines, including milling machines, routers, and lathes. It provides smooth, high-precision control over stepper and servo motors, ensuring accurate movements.

Built-in Programmable Logic (PLC)

Unlike basic breakout boards, the PoKeys57CNC includes an integrated programmable logic controller (PLC). This allows users to implement custom logic, automate tasks, and handle inputs/outputs without relying solely on external software.

Extensive I/O Capabilities

With 57 configurable I/O pins, the PoKeys57CNC offers flexibility for connecting limit switches, probes, spindle controls, and other peripherals. This eliminates the need for additional expansion boards in many setups.

Compatibility with Mach3 and Other Software

The PoKeys57CNC works seamlessly with Mach3, one of the most widely used CNC control programs. It also supports other CNC software, making it adaptable to different workflows.

USB and Ethernet Connectivity

The device supports both USB and Ethernet connections, providing reliable communication with your control PC. Ethernet connectivity is particularly useful for industrial environments where long cable runs or noise immunity are concerns.

How PoKeys57CNC Improves CNC Performance

Simplified Wiring and Setup

Traditional CNC setups often require multiple breakout boards and complex wiring. The PoKeys57CNC consolidates many functions into a single unit, reducing clutter and potential points of failure.

Enhanced Real-Time Processing

Thanks to its onboard processor, the PoKeys57CNC can handle time-critical tasks independently, reducing latency and improving responsiveness compared to software-only solutions.

Customizable for Unique CNC Applications

Whether you need custom macros, automated tool changes, or specialized sensor integrations, the PoKeys57CNC’s programmability allows for tailored CNC solutions.

Who Should Use PoKeys57CNC?

- Hobbyists looking for an affordable yet powerful CNC controller.

- Professionals needing reliability and expandability for industrial machines.

- DIY CNC builders who want a flexible, all-in-one control solution.

The PoKeys57CNC is more than just a breakout board—it’s a smart motion controller that enhances CNC precision, simplifies wiring, and adds automation capabilities. Whether you’re upgrading an existing machine or building a new one, the PoKeys57CNC provides the features and reliability needed for high-performance CNC operations.

Next, we’ll explore the PoKeys57CNC pinout and how to properly configure it for your CNC setup.

Understanding the PoKeys57CNC Pinout: A Complete Wiring Guide

Properly configuring the PoKeys57CNC pinout is essential for building a reliable CNC system. This versatile controller provides 57 configurable I/O pins, each serving specific functions in motor control, limit switching, and peripheral integration. Mastering these connections ensures optimal machine performance while preventing electrical issues.

Motor Control Connections

The PoKeys57CNC delivers precise movement through its dedicated motor control pins. Each axis requires three critical connections: the step pin sends pulse signals to the motor driver, the direction pin controls rotational orientation, and the enable pin activates the driver circuitry. These signals must maintain clean electrical paths, with proper grounding to prevent signal degradation. High-quality shielded cables prove invaluable here, especially when running wires near power cables or variable frequency drives that could introduce electromagnetic interference.

Limit and Home Switch Wiring

Safety and repeatability depend on correctly configured limit switches. The PoKeys57CNC accommodates both normally open and normally closed switch configurations, with best practices suggesting NC wiring for fail-safe operation. Each axis typically requires three switches – two for maximum travel limits and one for homing. The controller’s input pins feature noise filtering capabilities, but additional software debouncing in Mach3 further enhances reliability. Proper switch mounting and adjustment prevents false triggers while ensuring the machine stops precisely at its mechanical limits.

Spindle and Coolant System Integration

Precision machining demands accurate spindle control, achieved through the PoKeys57CNC’s PWM-capable output pins. These generate variable speed signals compatible with most VFD units, while dedicated relay outputs handle coolant pump activation. The controller’s ability to synchronize spindle commands with motion operations enables advanced techniques like rigid tapping. When wiring these systems, attention to voltage levels proves critical, as some spindle interfaces require opto-isolated connections to protect the controller from electrical noise.

General Purpose I/O and Expansion

Beyond core CNC functions, the PoKeys57CNC’s remaining pins serve as configurable general-purpose inputs and outputs. These facilitate advanced machine features including tool changers, probe interfaces, and operator controls. The flexible architecture allows reassignment of pins through software, enabling customization for unique applications. Many users employ these extra connections for machine status indicators, emergency stop circuits, or automated dust collection triggers. The controller’s support for both 5V and 24V logic levels accommodates diverse industrial components.

Optimizing Electrical Performance

Successful implementation requires careful electrical planning. Segregating signal cables from power lines minimizes interference, while proper grounding techniques prevent erratic behavior. The controller’s compact design simplifies wiring but demands organized cable management. Many experienced builders recommend testing each subsystem individually before full integration, using the PoKeys diagnostic tools to verify signal integrity. Documentation plays an equally important role – maintaining a detailed pinout reference prevents confusion during troubleshooting or future upgrades.

Understanding these connection principles transforms the PoKeys57CNC from a simple interface board into a powerful machine control center. The next section will explore configuring Mach3 limit switches to complete your safety-critical setup.

Configuring Mach3 Limit Switches for Optimal CNC Safety and Precision

Limit switches serve as the nervous system of your CNC machine, providing essential feedback about the physical position of machine components. When properly configured in Mach3 with your PoKeys57CNC controller, these switches perform three vital functions: establishing home positions, preventing over-travel crashes, and enabling safe machine operation. The precision of your entire machining process depends on their correct installation and configuration.

Selecting the Right Switch Type and Configuration

Two primary switch configurations exist for CNC applications: Normally Open (NO) and Normally Closed (NC). Industry professionals overwhelmingly recommend NC configurations for critical safety applications because they create a continuous circuit that immediately alerts the system if any connection fails. The PoKeys57CNC accommodates both types, but NC wiring provides inherent fail-safe protection – if a wire breaks or connection fails, the machine interprets this as a triggered limit condition and stops movement.

Physical Installation Considerations

Proper physical placement of limit switches significantly impacts their effectiveness. Install switches with enough mechanical advantage to ensure consistent triggering, typically using adjustable mounting brackets. Consider adding redundant switches for critical axes or implementing both mechanical and soft limits for maximum protection. The homing switch should be positioned to establish a precise, repeatable zero position, often using a separate, higher-precision switch than the limit switches.

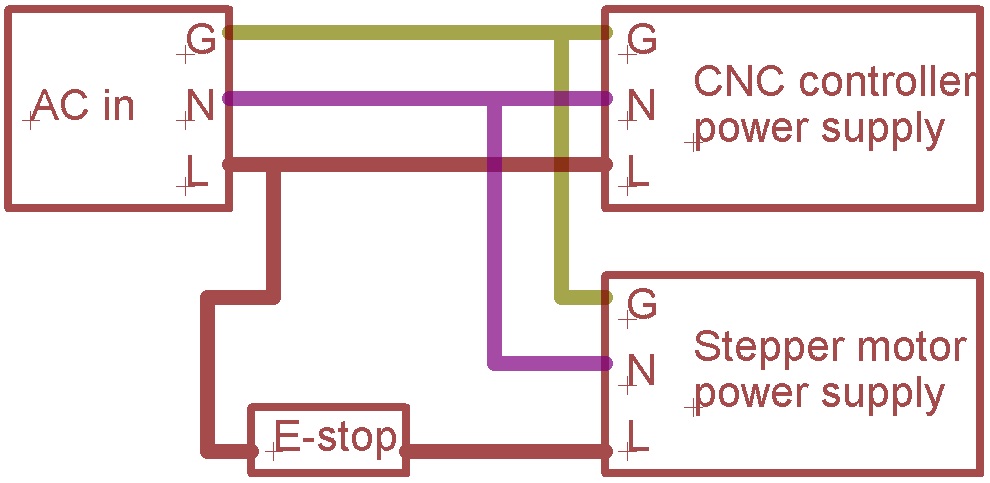

Electrical Connection Best Practices

When wiring limit switches to your PoKeys57CNC, use shielded cable for all long runs and maintain proper grounding to minimize electrical noise. The controller’s input circuits should match your switch voltage specifications, with appropriate current-limiting resistors if needed. For machines with multiple switches per axis, consider series wiring for limit switches (creating a single trigger circuit) while keeping the homing switch on a separate input for more precise control.

Mach3 Software Configuration

Within Mach3, navigate to the Ports and Pins configuration to assign your PoKeys57CNC inputs to limit switch functions. The software allows for sophisticated debounce settings to prevent false triggers from switch vibration. Configure the response behavior carefully – most setups should use an immediate stop (kill) response for limit triggers, while homing switches might use a controlled deceleration. The motor tuning screen should include appropriate slow-down distances to prevent overrun during homing sequences.

Testing and Troubleshooting Procedures

After configuration, systematically test each switch by manually triggering it while observing Mach3’s diagnostic screen. Verify that the correct input lights up and that the machine responds appropriately. Common issues include reversed switch polarity, insufficient debounce settings, or mechanical misalignment. The PoKeys57CNC diagnostic tools can help isolate electrical problems, while Mach3’s signal monitoring shows real-time input status.

Advanced Limit Switch Strategies

For professional installations, consider implementing these enhanced configurations:

- Dual-switch homing for improved repeatability

- Separate soft limits in Mach3 as a secondary protection layer

- Optical or magnetic non-contact switches in dusty environments

- Emergency stop circuits that incorporate limit switch status

Properly configured limit switches not only protect your machine from damage but also contribute to machining accuracy by ensuring consistent homing and workspace boundaries. The next section will guide you through essential Mach3 tutorial CNC resources to master your machine’s full capabilities.

Mastering CNC Operations: Essential Mach3 Tutorial for Beginners and Pros

Mach3 remains one of the most widely used CNC control programs, offering powerful features for machine operation while maintaining accessibility for beginners. This tutorial covers fundamental concepts through advanced techniques to help you maximize your PoKeys57CNC-equipped machine. Whether you’re setting up your first CNC router or optimizing a production mill, understanding Mach3’s interface and capabilities is crucial for successful machining operations.

Initial Setup and Configuration

The first step involves configuring Mach3 to communicate with your PoKeys57CNC controller. Begin by installing the correct plugin or driver for your hardware, then access the Config > Ports and Pins menu to establish proper signal mapping. Pay special attention to motor tuning parameters – incorrect steps-per-unit values will result in inaccurate movements. The motor tuning wizard helps calculate these values based on your specific drive system components, including microstepping settings and mechanical reduction ratios.

Creating and Running CNC Programs

Mach3 accepts standard G-code files, which can be generated from CAM software or written manually for simple operations. The software’s visual toolpath display allows operators to verify programs before execution. When running jobs, familiarize yourself with critical controls like feedrate override, spindle speed adjustment, and the optional stop function. The PoKeys57CNC’s integration enables smooth execution of complex toolpaths while maintaining precise coordination between axes and spindle control.

Advanced Operation Techniques

Beyond basic milling operations, Mach3 supports several advanced features:

- Rigid tapping cycles with synchronized spindle and Z-axis movement

- Custom macros for automated tool changes

- Probing routines for workpiece measurement

- 4th axis indexing and continuous rotation

- Tool length compensation and work offsets

These capabilities transform your machine from a simple cutter to a sophisticated manufacturing tool. The PoKeys57CNC’s programmable logic enhances these features by allowing custom I/O sequences and conditional operations.

Troubleshooting Common Issues

Even experienced users encounter occasional challenges with CNC operation. Typical issues include lost steps (often from excessive feedrates), communication errors (check USB/Ethernet connections), and unexpected limit triggers. Mach3’s diagnostic screens provide valuable real-time information about machine status, while the PoKeys57CNC’s monitoring tools help isolate hardware problems. Always verify emergency stop circuits and limit switches before troubleshooting other issues.

Optimizing Performance for Production

For professional users, several techniques can significantly improve machining efficiency:

- Implement tool libraries for quick setup

- Create custom screens for frequent operations

- Utilize Mach3’s scripting capabilities

- Fine-tune acceleration settings for your specific machine

- Establish standardized workholding procedures

The combination of Mach3’s software features and PoKeys57CNC’s hardware flexibility enables both high-precision work and efficient production workflows. Regular maintenance of both systems – including software updates and hardware inspections – ensures long-term reliability.

Next Steps in CNC Mastery

With these fundamentals mastered, operators can explore more sophisticated CNC techniques like high-speed machining strategies, advanced toolpath optimization, and integration with measurement systems. The PoKeys57CNC’s expandable architecture supports these growth paths while maintaining the reliability needed for professional applications. Remember that CNC operation represents a continuous learning process – even experienced machiners regularly discover new techniques and optimizations.

No More Imperfect Cuts: The Tech Behind Flawless CNC Plasma Performance

Simulate, Monitor, Control: The Trifecta of PoKeys57E, RC Interfaces, and DAQ Mastery

From Theory to Practice: Optimizing Stepper Motors with Drivers, Current & PCB Validation

Reimagining Railroads: The Role of USB I/O Controllers in Streamlining Model Railway Systems

Unlocking Your CNC’s Full Potential with PoKeys57CNC and Mach3

Throughout this comprehensive guide, we’ve explored how the powerful combination of PoKeys57CNC and Mach3 can transform your CNC operations. From understanding the versatile PoKeys57CNC pinout to mastering Mach3 limit switch configurations and navigating essential Mach3 tutorial CNC concepts, you now possess the knowledge to optimize your machine’s performance, safety, and precision.

The PoKeys57CNC stands out as more than just a motion controller – its intelligent design bridges the gap between complex CNC requirements and user-friendly implementation. When paired with Mach3’s robust control software, you gain access to professional-grade features that elevate your machining capabilities while maintaining accessibility for beginners.

Remember that proper configuration forms the foundation of successful CNC operation. Taking the time to correctly wire your PoKeys57CNC pinout, carefully set up your Mach3 limit switches, and thoroughly understand core Mach3 tutorial CNC principles will pay dividends in machine reliability and output quality. These systems offer remarkable flexibility – as your skills grow, you can explore advanced functionalities like custom macros, automated tool changes, and precision probing routines.

Whether you’re a hobbyist building your first CNC router or a professional optimizing a production workflow, the PoKeys57CNC and Mach3 combination provides the tools you need to push your machining capabilities forward. By applying the knowledge from this guide, you’re well-equipped to tackle projects with greater confidence, efficiency, and precision. The journey of CNC mastery continues – each project presents new opportunities to refine your skills and discover innovative applications for these powerful tools.