In the world of modern metal fabrication, precision and efficiency are paramount. Among the most advanced technologies driving this industry forward is CNC plasma cutting, a process that combines computer numerical control (CNC) with high-temperature plasma arcs to slice through metal with incredible accuracy. However, as demands for precision increase, so does the need for smarter, more adaptive systems.

One such innovation is PlasmaSensOut, a cutting-edge sensing technology that enhances plasma cutting by providing real-time feedback and adjustments. Alongside this, advancements in CNC plasma Z-axis and floating head mechanisms ensure consistent cut quality, even on uneven surfaces.

This article explores these three critical aspects of plasma cutting technology:

PlasmaSensOut – The intelligent sensing system revolutionizing precision.

What is CNC Plasma Cutting? – A breakdown of the core technology.

CNC Plasma Z-Axis & Floating Head – How height control ensures flawless cuts.

By understanding these components, manufacturers and fabricators can optimize their workflows, reduce waste, and achieve superior results.

PlasmaSensOut – The Smart Sensing Revolution in CNC Plasma Cutting

PlasmaSensOut is a cutting-edge sensing technology that is transforming the precision and efficiency of CNC plasma cutting. Unlike traditional systems that operate on fixed parameters, PlasmaSensOut integrates real-time feedback mechanisms to dynamically adjust torch height, arc voltage, and cutting speed. This innovation ensures optimal performance, even when working with uneven or warped materials.

How PlasmaSensOut Works

At its core, PlasmaSensOut uses advanced sensors to monitor key variables during the cutting process. These sensors detect fluctuations in:

- Arc voltage – Ensuring consistent energy delivery.

- Torch-to-work distance – Automatically adjusting the Z-axis for optimal cut quality.

- Material surface conditions – Compensating for warping or rust.

By continuously analyzing this data, PlasmaSensOut makes micro-adjustments to maintain precision, reducing errors and material waste.

Benefits of PlasmaSensOut in CNC Plasma Cutting

Enhanced Precision – By detecting and correcting deviations in real time, PlasmaSensOut ensures cleaner, more accurate cuts.

Reduced Downtime – Automatic adjustments minimize the need for manual recalibration.

Improved Material Utilization – Fewer errors mean less scrap metal and lower costs.

Adaptability to Challenging Materials – Even rusty or uneven surfaces can be cut smoothly.

Applications of PlasmaSensOut

This technology is particularly valuable in industries where precision is non-negotiable, such as:

- Aerospace – Cutting complex components from high-grade metals.

- Automotive – Fabricating parts with tight tolerances.

- Heavy machinery – Handling thick, uneven steel plates.

The Future of PlasmaSensOut

As CNC plasma cutting evolves, PlasmaSensOut is expected to integrate AI-driven predictive adjustments, further refining cut quality and speed. Manufacturers adopting this technology will gain a competitive edge through superior efficiency and reliability.

By leveraging PlasmaSensOut, fabricators can push the boundaries of what’s possible with CNC plasma cutting, ensuring flawless results every time.

What is CNC Plasma Cutting? The Core Technology Explained

CNC plasma cutting is a highly efficient metal fabrication process that combines computer-controlled precision with the intense heat of a plasma arc to cut through electrically conductive materials. Unlike traditional mechanical cutting methods, CNC plasma cutting offers faster speeds, cleaner edges, and greater versatility—making it indispensable in modern manufacturing.

How CNC Plasma Cutting Works

The CNC plasma cutting process involves several key components working in unison:

Plasma Torch – The cutting tool that generates a superheated plasma arc (up to 30,000°F) to melt metal.

CNC Controller – A computer-guided system that directs the torch along pre-programmed cutting paths.

Power Supply – Provides the electrical energy needed to sustain the plasma arc.

Gas Delivery System – Typically uses compressed air, nitrogen, or argon to create and stabilize the plasma jet.

When activated, the CNC plasma cutting system follows digital blueprints (CAD/CAM files) to execute precise cuts, from simple shapes to intricate designs.

Advantages of CNC Plasma Cutting

Compared to laser or waterjet cutting, CNC plasma cutting offers unique benefits:

- Cost-Effectiveness – Lower operational costs than laser systems, especially for thick metals.

- High Speed – Cuts faster than oxy-fuel methods, boosting productivity.

- Material Versatility – Works on steel, aluminum, copper, and other conductive metals.

- Minimal Finishing Required – Produces smoother edges than traditional torch cutting.

Limitations and Considerations

While CNC plasma cutting is highly efficient, it has some constraints:

- Heat-Affected Zone (HAZ) – The intense heat can slightly alter material properties near cuts.

- Precision Limits – Tolerances are slightly looser than laser cutting (typically ±0.5mm).

- Energy Consumption – Requires substantial power for industrial-scale operations.

Industries That Rely on CNC Plasma Cutting

From small workshops to large factories, CNC plasma cutting is widely used in:

- Shipbuilding – Cutting thick steel plates for hulls and decks.

- Construction – Fabricating structural beams and brackets.

- Art & Decoration – Creating intricate metal sculptures and signage.

The Future of CNC Plasma Cutting

With advancements like PlasmaSensOut and automated material handling, CNC plasma cutting continues to evolve. Future systems may integrate AI for real-time optimization, further enhancing speed and precision.

For manufacturers seeking a balance of affordability, speed, and versatility, CNC plasma cutting remains a go-to solution.

Simulate, Monitor, Control: The Trifecta of PoKeys57E, RC Interfaces, and DAQ Mastery

From Theory to Practice: Optimizing Stepper Motors with Drivers, Current & PCB Validation

Other articles about technology

CNC Plasma Z-Axis & Floating Head – The Critical Role of Height Control in Precision Cutting

At the heart of modern plasma cutting systems lies the sophisticated interplay between the CNC plasma Z-axis and floating head mechanisms. These components work tirelessly to maintain the delicate balance between torch and workpiece, ensuring each cut meets exacting quality standards regardless of material imperfections. The importance of this technology cannot be overstated in industrial applications where precision directly impacts productivity and profitability.

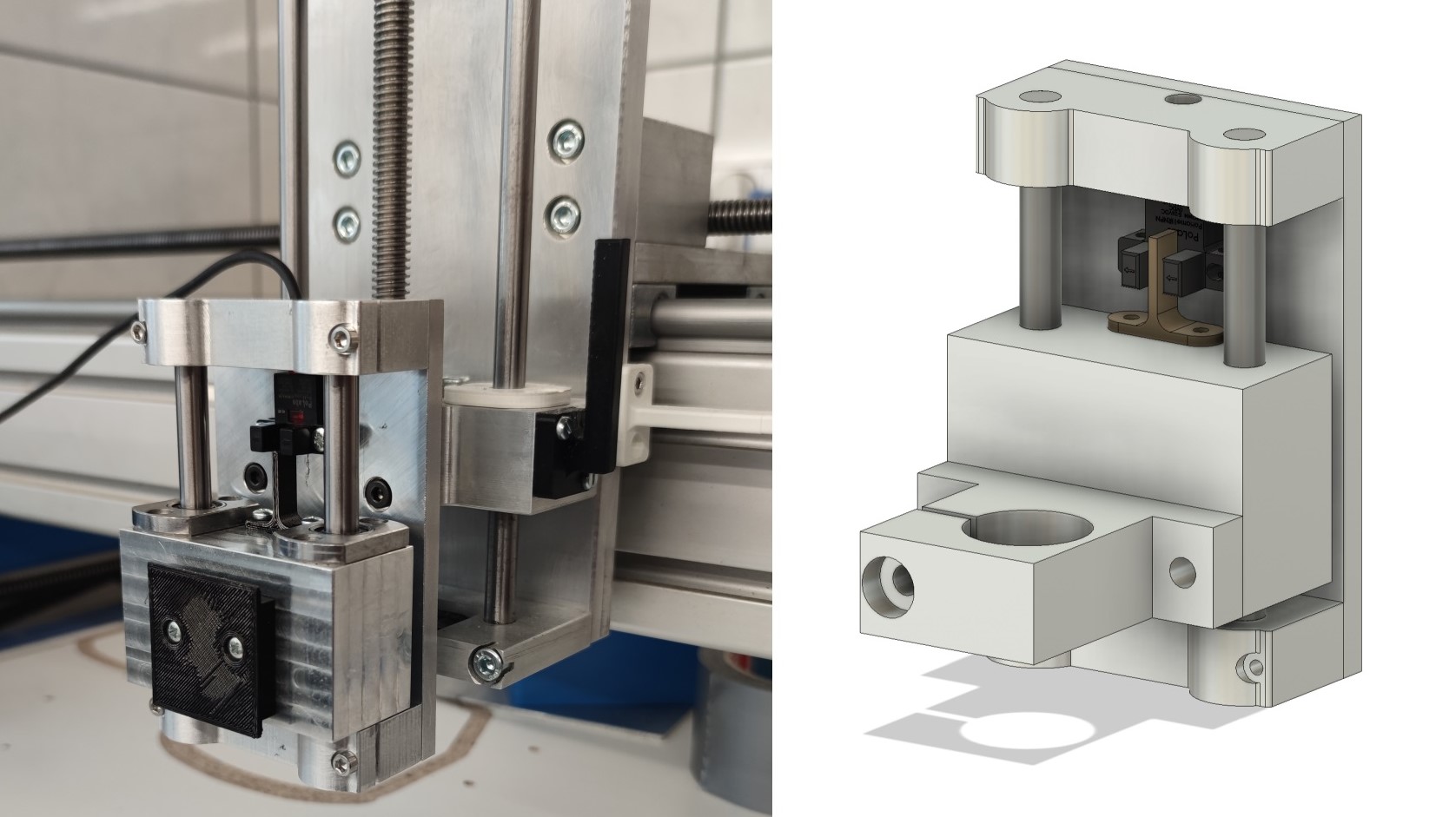

The Z-axis system functions as the vertical positioning brain of the plasma cutter, driven by either servo or stepper motors that respond to real-time feedback. This precise vertical movement works in concert with the floating head’s mechanical intelligence – a spring-loaded or pneumatic assembly that physically rides along the material surface. Together with Arc Voltage Height Control technology, these components create a dynamic system that constantly monitors and adjusts for optimal cutting conditions.

What makes this technology truly remarkable is its ability to compensate for the realities of metal fabrication. Warped sheets, rusted surfaces, and heat-distorted materials that would challenge conventional systems become manageable through continuous micro-adjustments. The floating head gently traces the material’s topography while the Z-axis makes instantaneous corrections, maintaining that critical 1.5-3mm standoff distance where plasma cutting performs at its best.

The benefits of this technology manifest in several crucial ways. Cut quality improves dramatically as the system maintains consistent kerf width and minimizes bevel angle variations. Consumable life extends significantly as proper standoff distance prevents nozzle crashes and optimizes arc formation. Perhaps most importantly, process reliability increases substantially, allowing for uninterrupted production runs even with imperfect materials.

When integrated with PlasmaSensOut technology, the Z-axis and floating head system reaches new levels of performance. The combination creates a closed-loop system where sensors detect material variations and the height control responds immediately. This proves particularly valuable in specialized applications like pipe cutting or artistic metalwork where surface conditions change constantly.

Maintaining these systems requires attention to several key areas. Regular cleaning and lubrication of linear guides ensures smooth operation, while monthly sensor calibrations preserve accuracy. Technicians must remain vigilant for mechanical wear on floating head components and stay current with software updates to maintain peak performance.

Looking ahead, the future of height control technology promises even greater capabilities. Artificial intelligence stands to revolutionize these systems with predictive adjustment algorithms, while hybrid sensor technologies may offer unprecedented measurement accuracy. Wireless floating head designs could eliminate current cable management challenges, further streamlining operations.

For fabrication shops evaluating plasma cutting systems, the sophistication of the Z-axis and floating head technology should be a primary consideration. These components represent more than just another feature – they are fundamental to achieving consistent, high-quality results that keep operations competitive in an increasingly demanding marketplace. As material challenges grow more complex and quality expectations rise, advanced height control systems will continue to play a pivotal role in successful metal fabrication.

The Future of Precision Plasma Cutting – Where Innovation Meets Performance

The evolution of CNC plasma cutting has reached new heights with advancements like PlasmaSensOut, intelligent Z-axis and floating head systems, and increasingly sophisticated automation. Together, these technologies are reshaping metal fabrication, offering unprecedented precision, efficiency, and adaptability.

PlasmaSensOut has emerged as a game-changer, providing real-time feedback that allows plasma cutters to self-correct for material inconsistencies, ensuring cleaner cuts and longer consumable life. Meanwhile, the integration of advanced Z-axis and floating head mechanisms guarantees optimal torch positioning, even on warped or uneven surfaces. These innovations work in harmony with core CNC plasma cutting technology to deliver faster, more reliable results across industries—from heavy industrial manufacturing to intricate artistic metalwork.

Looking ahead, the next frontier lies in AI-driven optimization and predictive maintenance, where machine learning algorithms will further refine cut quality while minimizing downtime. Wireless sensing, hybrid laser-plasma guidance systems, and even more responsive height control mechanisms will continue to push the boundaries of what’s possible.

For manufacturers and fabricators, investing in these cutting-edge technologies is no longer optional—it’s essential for staying competitive. As CNC plasma cutting systems become smarter, faster, and more precise, businesses that embrace these innovations will lead the industry in quality, efficiency, and cost-effectiveness.

The future of metal fabrication is here, and it’s powered by intelligent plasma cutting technology. The only question that remains is: Are you ready to take full advantage of it?