In the evolving world of industrial automation and smart electronics, the bridge between software control and hardware execution has never been more vital. The seamless communication between digital commands and physical actions defines the efficiency and precision of modern systems, from home automation to complex industrial machinery. Among the crucial components that make this possible are I/O controllers, relay boards, and programmable relays, each playing a distinct yet interconnected role in managing signals, powering devices, and executing control logic.

As technology advances, the demand for smarter, more versatile, and highly reliable control systems continues to rise. Devices like the PoRelay8, an advanced 8 channel relay board, and sophisticated programmable relays illustrate how hardware design has evolved to meet the requirements of both industrial professionals and electronic enthusiasts. These components are not just about turning things on and off—they represent a fusion of intelligence, flexibility, and integration that enables automation systems to perform with remarkable efficiency.

Understanding how these devices operate, how they differ, and where they overlap provides valuable insight into the architecture of automation. Whether controlling motors, lighting systems, or industrial processes, these tools serve as the foundation upon which precision control and digital responsiveness are built. In the following chapters, we will explore each of these technologies in depth—examining what an I/O controller truly is, uncovering the capabilities of the PoRelay8, understanding the structure and functionality of an 8 channel relay board, and delving into the adaptability and intelligence of the programmable relay.

Each section will answer a central question, designed to provide clarity on both the technical and practical aspects of these essential components. By the end, you will not only understand their individual purposes but also appreciate how they complement one another in creating efficient, scalable, and intelligent automation solutions that power today’s connected world.

What is an I/O Controller and Why Is It Essential in Modern Automation?

An I/O controller, or input/output controller, is a central component in the communication chain between a computer or microcontroller and the devices it controls. In essence, the I/O controller acts as an intelligent intermediary, managing data flow between digital systems and the physical world. It reads input signals—such as those from sensors, switches, or buttons—and sends output commands to devices like motors, relays, and lights. Without an I/O controller, automation systems would struggle to interpret the real-time conditions of their environment or respond with the necessary precision and timing.

At its core, the I/O controller converts raw signals into usable data for software-based systems. For example, when a temperature sensor detects a rise beyond a preset threshold, the I/O controller processes that signal and instructs an output device—perhaps a fan or cooling unit—to activate. This cycle of sensing, interpreting, and responding forms the backbone of modern automation. What makes the I/O controller indispensable is its ability to handle multiple simultaneous inputs and outputs, ensuring synchronization across complex processes.

In industrial contexts, an I/O controller can be found at the heart of programmable logic controllers (PLCs), robotics systems, and smart manufacturing lines. It coordinates communication between high-level control software and the machinery executing physical operations. For instance, when a production robot assembles a component, every sensor reading and actuator movement passes through an I/O controller. The speed and accuracy of this interaction directly affect efficiency, safety, and product quality.

Beyond factories, the influence of I/O controllers extends to home automation, environmental monitoring, and IoT (Internet of Things) ecosystems. In smart homes, an I/O controller might receive data from motion sensors or thermostats and send output signals to lighting systems, HVAC units, or security cameras. The ability to integrate analog and digital signals, wireless communication protocols, and even cloud connectivity demonstrates the adaptability of these controllers to various environments.

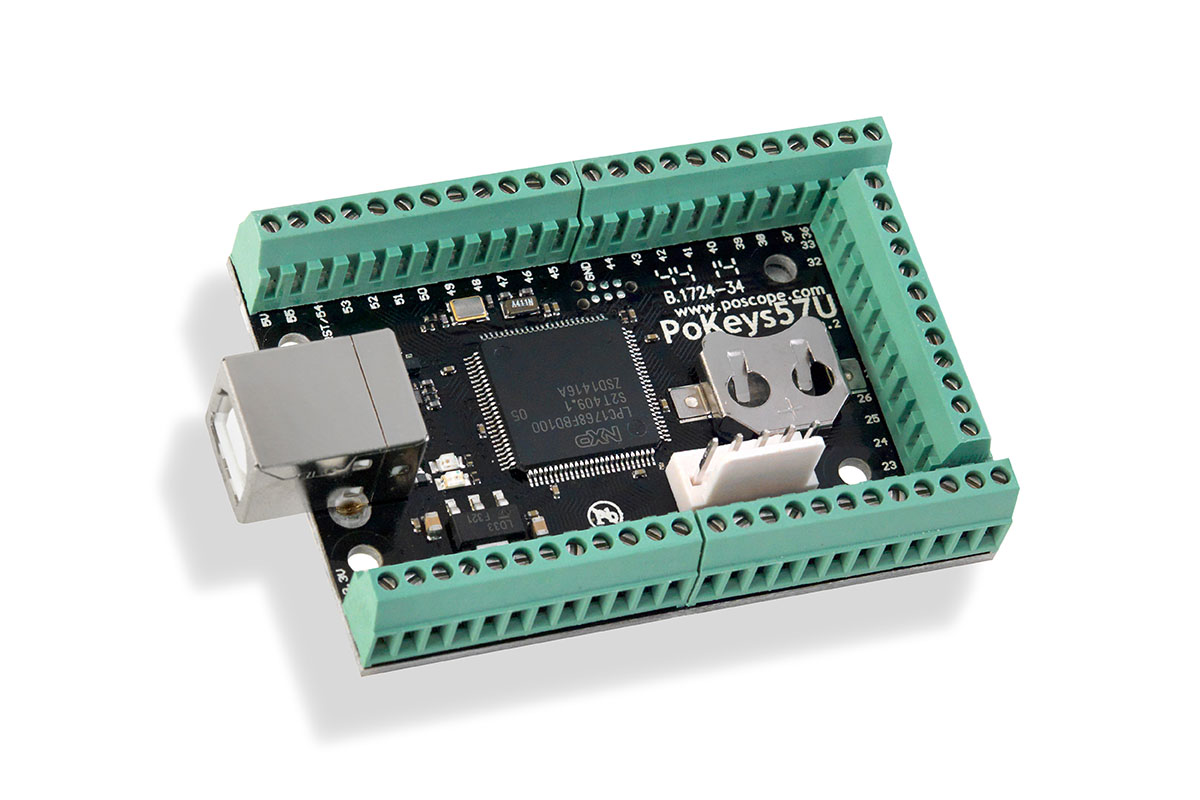

Modern I/O controllers often include features like onboard processing power, communication interfaces (such as USB, Ethernet, or RS-485), and compatibility with programmable software platforms. These capabilities allow engineers to configure, monitor, and adjust performance in real time. Advanced systems can even execute local logic, reducing the need for constant supervision from a central computer.

Ultimately, the I/O controller is more than just a signal manager—it is the conductor of an orchestra of devices, ensuring that each component performs its role in harmony. By bridging the gap between code and circuitry, it enables automation systems to think, react, and evolve. In an era defined by digital transformation and interconnected technologies, the I/O controller remains one of the most critical elements for achieving intelligent and responsive control across industries.

What Is the PoRelay8 and How Does It Enhance Hardware Control?

The PoRelay8 is a versatile and powerful relay control module designed to provide seamless interaction between digital systems and electrical devices. As its name suggests, the PoRelay8 features eight independent relay channels, making it ideal for applications that require multiple on/off controls through a single interface. Whether used in industrial automation, laboratory setups, or home electronics projects, the PoRelay8 delivers a reliable and programmable solution for managing electrical loads with precision and safety.

At its foundation, the PoRelay8 functions as an 8 channel relay board, but its design and functionality go beyond simple switching. It is often integrated with intelligent communication protocols that allow microcontrollers, PLCs, or computers to send commands to each of its eight relays. This means users can remotely control devices like motors, pumps, solenoids, or lighting circuits with exact timing and logical coordination. The name “PoRelay8” has become synonymous with efficiency and compact control, particularly in environments where space is limited but versatility is required.

One of the defining features of the PoRelay8 is its programmability. Unlike traditional relay boards that operate only in response to physical inputs, the PoRelay8 can be programmed to execute predefined sequences, respond to sensor data, or communicate with external software systems. This programmability transforms it from a passive component into an active participant in automation. Engineers can script custom control logic, set time-based operations, or even integrate feedback loops that enable dynamic adjustments based on system conditions.

The electrical design of the PoRelay8 ensures both stability and safety. Each relay channel is isolated, preventing voltage interference and protecting sensitive control circuitry from high-power loads. This isolation is especially important when working with mixed-voltage systems, such as a 5V logic signal controlling a 230V motor. The PoRelay8’s durable relays are built to handle substantial current ratings, allowing them to manage industrial-grade loads while maintaining long-term reliability.

Furthermore, the PoRelay8 often includes indicator LEDs for each channel, providing immediate visual feedback of relay states. This small but practical feature simplifies troubleshooting and monitoring, especially during development or testing phases. In many configurations, the board also supports external power sources, giving users flexibility to tailor power management according to their application’s needs.

The integration potential of the PoRelay8 is another reason for its widespread adoption. It communicates effortlessly with common control platforms such as Raspberry Pi, Arduino, or industrial PLC systems. This broad compatibility makes it an accessible choice for both professionals and hobbyists. By using a PoRelay8, developers can design systems that manage everything from automated irrigation setups and environmental controls to robotics and remote power distribution units.

Ultimately, the PoRelay8 stands as a prime example of how modern 8 channel relay boards are evolving to meet complex demands. It represents a shift toward smarter, more modular automation hardware—bridging traditional relay control with programmable intelligence. Through its combination of reliability, flexibility, and ease of integration, the PoRelay8 empowers users to build efficient, scalable, and highly responsive systems that bring digital control to life in the physical world.

How Does an 8 Channel Relay Board Function and Why Is It So Useful?

An 8 channel relay board serves as a critical interface between low-voltage digital systems and high-voltage electrical devices. It allows a microcontroller, PLC, or computer to control multiple circuits safely and efficiently. Each of the eight relays on the board acts as an electrically operated switch, capable of turning devices on or off according to digital signals received from the control unit. The 8 channel relay board is a cornerstone of automation, bridging logic-level control with real-world electrical power.

At its core, an 8 channel relay board converts small control voltages—typically 3.3V or 5V signals—into the power required to operate machinery, lighting, or other high-current equipment. When the control signal energizes a relay coil, it magnetically pulls a contact arm, closing or opening a circuit. This allows the board to handle multiple devices independently, each on its own dedicated channel. Because of this architecture, the 8 channel relay board provides the flexibility to manage various loads simultaneously, from motors and pumps to heating elements or alarms.

One of the greatest advantages of an 8 channel relay board is its scalability. Whether used in home automation, robotics, or industrial control systems, it provides an organized and modular approach to managing multiple electrical outputs. For instance, in a smart home setup, one board might control lighting in different rooms, fans, or door locks—all from a single microcontroller. In an industrial context, it could manage conveyor belts, solenoid valves, or cooling systems, ensuring synchronized operation across complex processes.

Safety and isolation are fundamental design features of any quality 8 channel relay board. Each relay is electrically isolated from the others, typically using optocouplers to separate the low-voltage control signals from high-voltage circuits. This isolation not only protects delicate microcontrollers from voltage spikes but also ensures system stability and operator safety. Boards designed with robust relays can handle both AC and DC loads, making them adaptable to diverse power requirements.

The 8 channel relay board is also known for its straightforward operation. Developers can easily connect it to popular platforms like Arduino, Raspberry Pi, or ESP32, using digital pins to send HIGH or LOW signals that activate individual relays. Many boards come with built-in LEDs to indicate the status of each relay, providing immediate visual confirmation of system behavior. Such convenience is invaluable during development, testing, and maintenance, minimizing the time spent diagnosing control issues.

Beyond simplicity, the 8 channel relay board also supports advanced automation. By integrating it with sensors, timers, and programmable logic, users can design dynamic systems that react automatically to environmental inputs. For example, a board could trigger ventilation when temperature sensors detect excess heat or activate pumps when soil moisture falls below a threshold. This combination of manual and automated control highlights the flexibility of relay-based design in both small-scale and large-scale projects.

In summary, the 8 channel relay board remains an essential component of modern control systems. It embodies the balance between simplicity and capability, allowing digital systems to influence high-power devices safely and reliably. From educational experiments to industrial production lines, its versatility, protection features, and adaptability make it an indispensable tool for anyone working with electrical automation. The 8 channel relay board is more than a collection of switches—it is a gateway that transforms digital intelligence into tangible action.

What Is a Programmable Relay and How Does It Transform Automation?

A programmable relay is a highly versatile device that combines the functionality of traditional relays with the intelligence of software-based control. Unlike standard relays, which simply act as electrically operated switches, a programmable relay allows users to define complex logic, timing sequences, and conditional operations directly within the device. This capability makes it a cornerstone of modern automation systems, offering both flexibility and efficiency in controlling a wide range of electrical equipment.

At its core, the programmable relay receives input signals from sensors, switches, or digital controllers and processes these signals according to user-defined logic. Once the conditions are met, the relay executes output commands to control devices such as motors, pumps, lighting, or solenoids. What sets the programmable relay apart is its ability to perform logic operations locally, without the need for a separate PLC or microcontroller. This independence simplifies system design, reduces wiring complexity, and enhances reliability by minimizing potential points of failure.

The applications of programmable relays are diverse. In industrial automation, they can manage sequential machine operations, coordinate timing between multiple devices, or execute safety interlocks to prevent damage and ensure operator safety. In home automation, these relays can control lighting schedules, HVAC systems, and security devices, responding dynamically to inputs such as motion detection, temperature thresholds, or time-based triggers. By integrating the decision-making process directly into the relay, the programmable relay enables smarter, more responsive control with minimal external hardware.

One of the main advantages of a programmable relay is its ease of configuration. Many devices come with intuitive programming interfaces, allowing users to set timers, counters, or conditional logic through software or onboard displays. Unlike a standard 8 channel relay board, which requires external programming via a microcontroller, the programmable relay embeds intelligence directly, making it suitable for smaller projects or systems where simplicity and compactness are essential. Advanced models even support communication protocols such as Modbus, Ethernet, or wireless interfaces, allowing integration into larger networked automation systems.

Safety and reliability are also key benefits of the programmable relay. By allowing precise control over timing, sequencing, and conditions for activation, it reduces the risk of simultaneous operation of conflicting devices or overload conditions. Additionally, built-in diagnostic features and status indicators often provide real-time feedback, making troubleshooting and maintenance easier. This ensures that systems using a programmable relay can operate efficiently and consistently, even in demanding environments.

Ultimately, the programmable relay represents the evolution of relay technology from simple switching devices to intelligent automation components. It combines the familiar robustness of traditional relays with advanced control capabilities, offering a compact, flexible, and reliable solution for both industrial and residential applications. By embedding logic and decision-making within the relay itself, the programmable relay transforms automation from reactive control to proactive management, enabling systems that are smarter, safer, and more adaptable than ever before.

Conclusion

The world of automation relies on a delicate balance between intelligence, control, and power, and devices like the I/O controller, PoRelay8, 8 channel relay board, and programmable relay exemplify how this balance is achieved. Each plays a unique role in translating digital commands into tangible actions, yet their combined capabilities define the versatility and efficiency of modern control systems. The I/O controller acts as the central interpreter, managing inputs and outputs with precision, while the PoRelay8 provides a compact, programmable solution for controlling multiple devices simultaneously. Meanwhile, the 8 channel relay board delivers organized and reliable high-power switching, and the programmable relay integrates intelligent logic directly into hardware, streamlining automation in both industrial and residential contexts.

Together, these components showcase the evolution of automation technology—from simple mechanical switching to sophisticated, software-driven control. They enable engineers, hobbyists, and system designers to build scalable, efficient, and responsive systems capable of handling complex tasks with minimal intervention. By understanding their functions, strengths, and interactions, users can design solutions that are not only effective but also safe, reliable, and adaptable to changing demands.

Ultimately, the integration of I/O controllers, PoRelay8 modules, 8 channel relay boards, and programmable relays represents a fusion of intelligence and action. They exemplify how modern automation systems can achieve precision, responsiveness, and flexibility, empowering a wide range of applications—from industrial production lines to smart homes. As technology continues to advance, these devices will remain at the heart of automation innovation, transforming how we control and interact with the world around us.